If you’re a carrier of fuel or other hazardous goods that cannot be taken into a test station, the difficulty and time it takes when a laden roller brake test is needed can be very stressful.

- Fuel must be offloaded safely before a trailer can enter the test station

- As tests must be performed laden, if the operator does not have the weights the test centre will charge for loads to be added

- Following the roller brake test, the fuel or other hazardous substance must then be loaded back onto the trailer at the place it was offloaded

The downtime and associated costs this causes is bad enough with just one asset, multiply that by a whole fleet and it becomes one huge logistical challenge. Thankfully, there is a solution.

EBPMS by Axscend is helping fleets all over the UK dynamically monitor their trailers brake performance and reduce their need for roller brake testing to just once a year at the annual MOT.

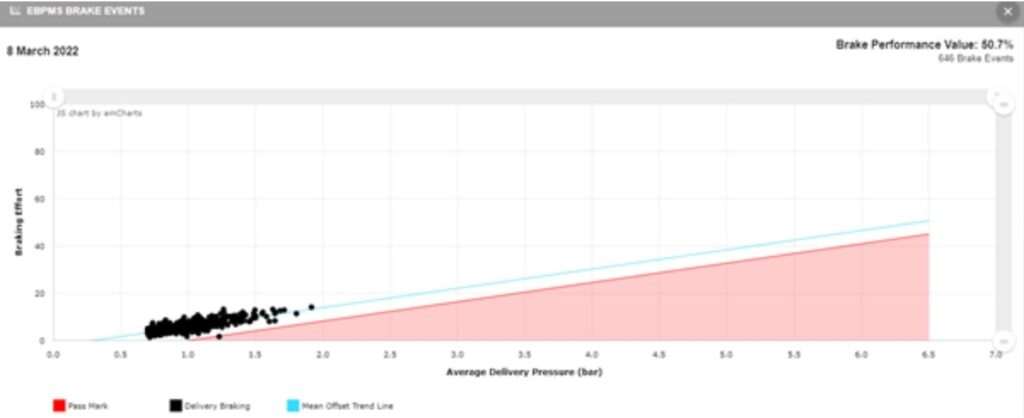

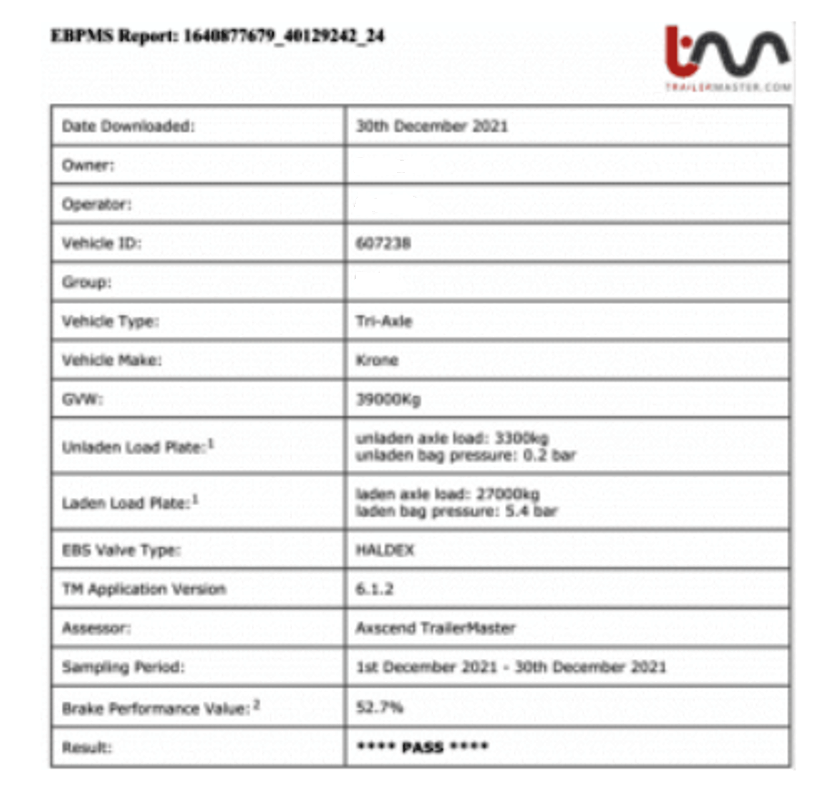

Giving operators complete visibility of their fleets brake status and performance, EBPMS connects to a trailer’s EBS (electronic braking system). The brake performance data is fed through to the TrailerMaster portal and colour coded. Green indicates all is ok, amber means something needs looking at, and red is critical and must be dealt with immediately. The resulting data is plotted in an easy-to-read graph against the DVSA pass mark. Reports for the DVSA are available and easily accessed from the web portal or app.

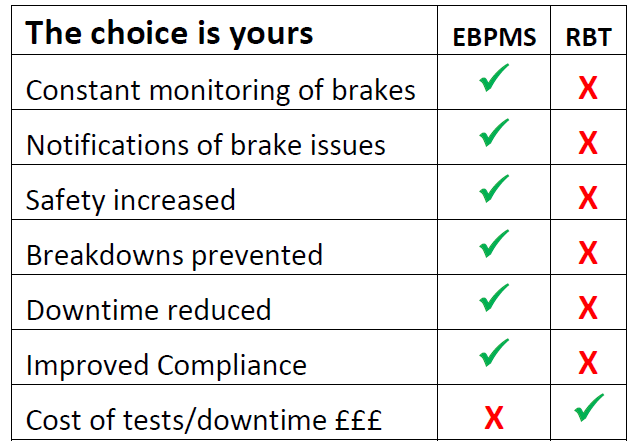

EBPMS has been included in the DVSA’s Guide to Roadworthiness. RBT or EBPMS, which would you choose?

Book a demo and find out how EBPMS could help your transport operation

Call 01303 842103 https://axscend.com/ebpms/